Molds

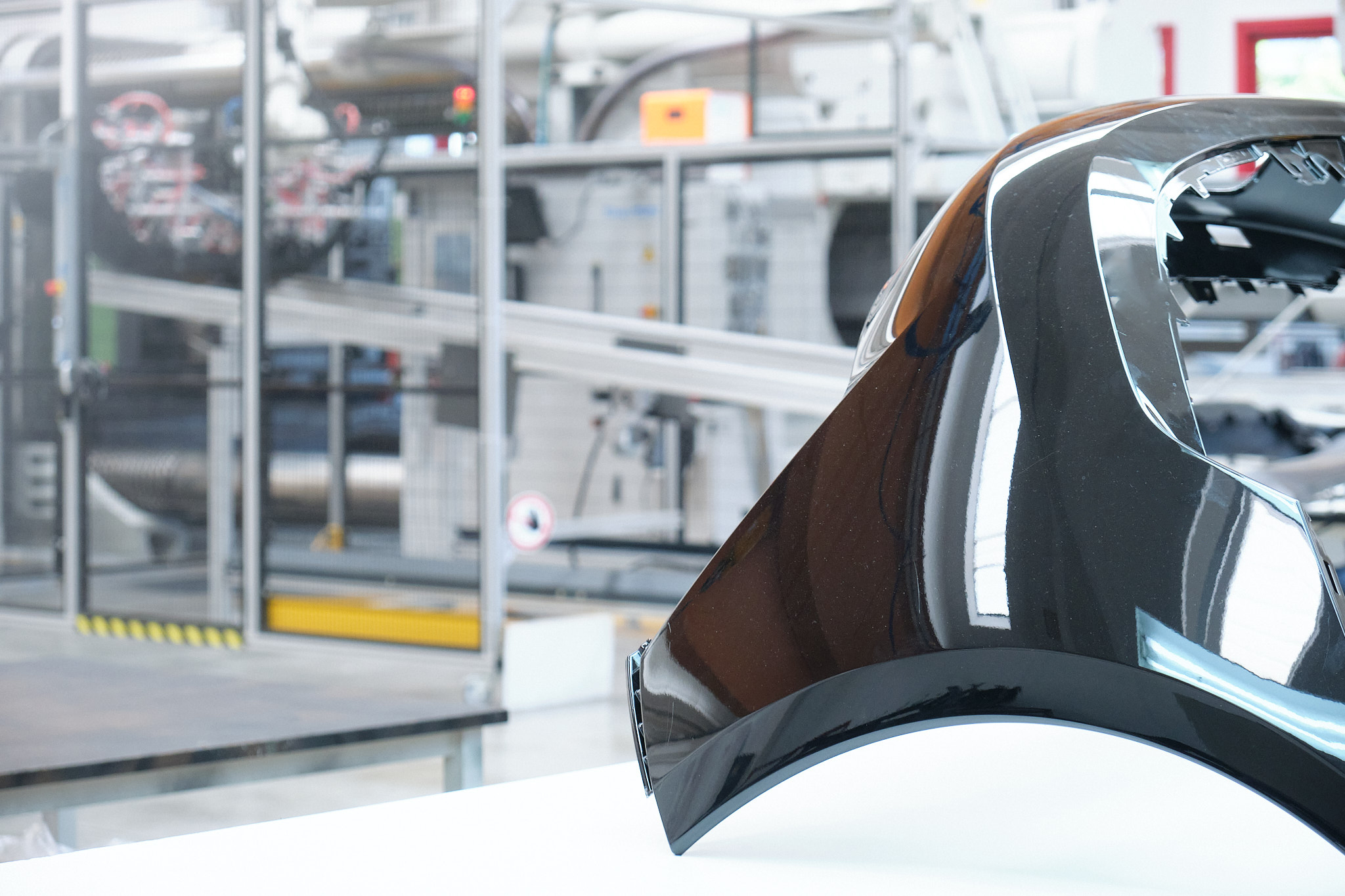

Tecnostampi builts molds that allow its customers to produce plastic components such as bumpers, spoilers, dashboards, reinforcements, etc.

With acquired experience and the use of the most modern technologies in the industry, we are able to create molds that meet the highest quality standards required by our customers.

History

Tecnostampi has a successful history in mold production for the automotive sector.

This activity started in 1967 by the current owner, Mr. Dino Conte, and has continued and developed under the name of Tecnostampi since 1978.

The company has consolidated its reputation for reliability and success over the years, thanks to its nearly 60 years of experience and targeted investments to improve production capabilities and facilities.

Services

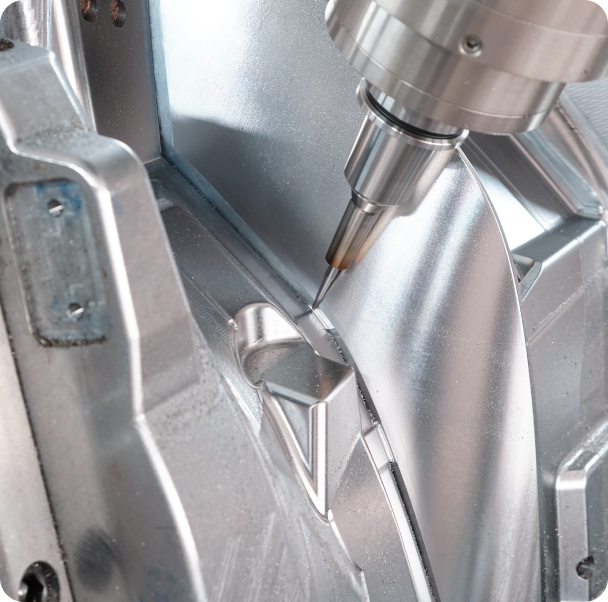

Specialized technical personnel use advanced software such as Catia and Siemens NX for mold design, supported by an industrial patent.

The equipment used for manufacturing includes machinery such as CNC milling machines, drills, spark erosion and spotting presses.

Main mold users (OEM)

Audi, BMW, Ford, Jaguar, Land-Rover, Mercedes, Mitsubishi, Porsche, Renault, Skoda, Stellantis Group, Tesla, Volkswagen

Export countries

Germany, Belgium, Spain, Mexico, South Africa, France, United States of America, England, Hungary, Slovakia, Sweden, China, Czech Republic, Brazil

Contact Tecnostampi for high-quality automotive molds.

Useful Links

© 2023 Tecnostampi SRL. VAT and VIES registration: 00557740123